Level Switches

What is a floating switch?

A float switch detects the liquid level in a container, tank or well. The floating part of the device is placed on top of liquid, and it will activate when the liquid rises or falls. Float switches can be used to control the level of wastewater and sewage pumps as well as raw water and liquid transfer pump at waterworks. They also serve for alarms when water levels are too high.

How does a Float switch work?

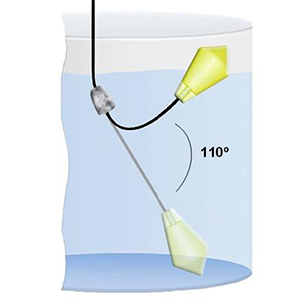

The float switch has a reed and a magnet that can be used to operate normally open (N/O), or normally closed. Switch action can be reversed by rotating the switch 180 degrees.

The switch is placed on top of the water level. As the fluid level changes, the reed will change (for example close or open) to a certain level. The internal mechanical switch closes or opens the electrical circuit by gravity, allowing it to turn on/off equipment such as a pump.

What are the materials used to make float switches?

- Nylon is used in oils, diesel and organic chemicals.

- Polypropylene – Acids and alkalis, detergents, oil, water, organic chemicals.

- Polyphenylene Sulphide (PPS). Used for chemicals that are more aggressive and at higher temperatures up to 120oC.

- Hydraulic fluids, chemicals, medical and food industries.

Features & Benefits

- Highly Flexible

- High mechanical load rating

- Insensitive to Turbulence

- Shock and Rupture-Proof

- WRAS Approvals

Showing all 7 results